About Me

Hi,

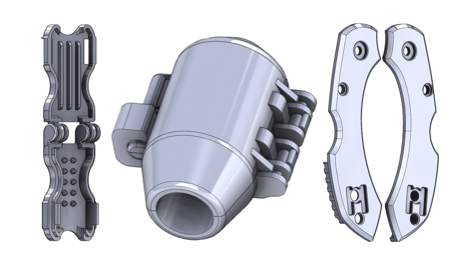

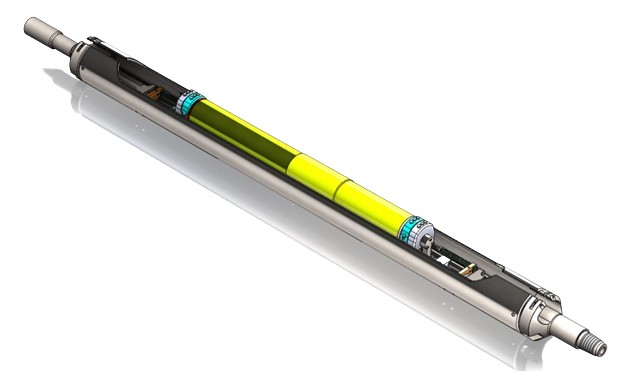

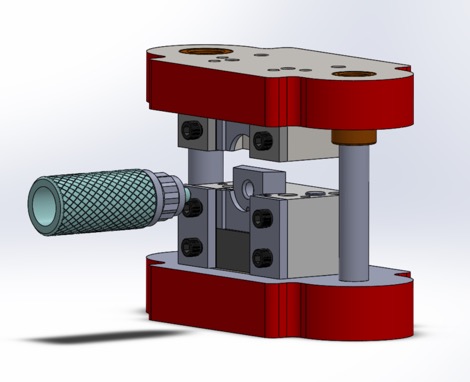

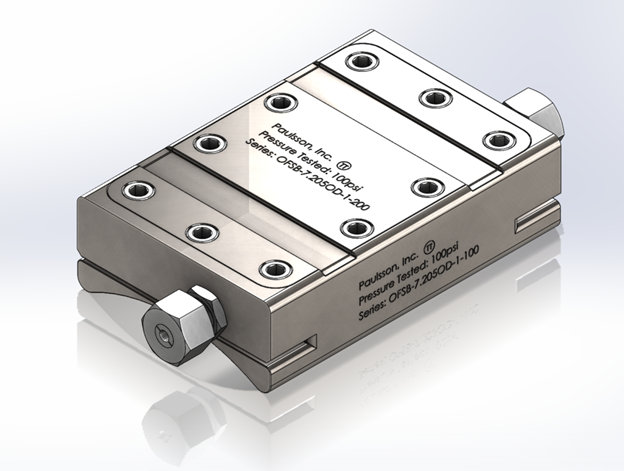

As a consultant and mechanical engineer by trade, I’m also an innovator and entrepreneur with over 6 years of experience in delivering data-driven solutions to complex challenges, particularly in R&D projects. I have earned a reputation as a strategic problem-solver, directing and managing full-cycle projects across the industrial, clean energy, medical, and e-commerce industries. Holding an EIT certification, I have a proven track record in product design, 3D modeling, FEA simulation, prototyping, testing, and MVP production for metal and plastic products.

Known for effectively managing clients, subcontractors, and company growth, I excel in leading teams, communicating complex ideas, and delivering innovative designs within budget constraints. My ability to collaborate across multidisciplinary teams allows me to simplify technical complexities and provide clear, actionable insights for stakeholders. I am also skilled in guiding clients based on consumer and market research, ensuring that their strategies align with market demands.

My notable accomplishments include developing patentable technologies, managing multimillion-dollar projects, and maintaining a 5-star rating with all projects at Clean Science Labs. My approach is characterized by resilience, high energy, and a proactive mindset, enabling me to drive projects from concept through to successful execution.

andrewrcecola@gmail.com